About Us

COMPANY SUMMARY

For over 30 years Cor-Tech Engineering has built a trusted reputation in manufacturing complex and precision-machined components, light to medium metal fabrications and assemblies.

At Cor-Tech, we understand the need for modernization. We have consistently invested in state of the art machinery to ensure that we are able to keep up with demand, and continue to produce quality products.

We operate an in house quality assurance program that conforms in all aspects to international standards. All procedures and testing are in strict conformance to quality plans, prepared to suit client requirements.

This allows us to be leaders in prototype development, and enables us to tackle complex projects, while still delivering timeously to our customers and never compromising on quality.

Additionally our welding procedure is certified by the SAIW. Cor-Tech is a ISO 9001:2015 certified organization.

PEOPLE & CULTURE

PEOPLE & CULTURE

At Cor-Tech, we believe that by uplifting our People to be the best, we become the best; therefore we have employed a capable workforce which continuously undergo training to further expand their capabilities and skills.

Cor-Tech Engineering is a certified level 2 BBBEE contributor.

MISSION

Manufacturing of the highest quality products & to offer service delivery beyond customer expectations.

vision

To be the first choice supplier to our customers.

values

Working with integrity and pride. Zero tolerance on defects. Continuous building & maintaining of customer relationships. By uplifting our people to be the best, we become the best.

LOCATION

LOCATION

Cor-Tech is conveniently located at 41 Knights Road, Knights, which is an Industrial area

with close proximities to other major industrial areas such as Isando, Jetpark, Dunswart, Wadeville and Anderbolt.

We are also conveniently close to major highway routes. Cor-Tech is based at one location with a total floor

area of approximately 2200 sq, housing six workshops, in-house inspection facilities and offices.

Cor-Tech has an International footprint with projects in Southern Africa and Saudi Arabia.

Through our international OEM customer, we continue to export to the USA, UK, India, Australia and China.

EXPERTISE

EXPERTISE

Historically, Cor-Tech’s expertise lied in the Mining sector where we worked in Underground and Opencast with

GOLD

COAL

PLATINUM

COPPER &

CHROME

GOLD

COAL

PLATINUM

COPPER &

CHROME

However, in recent years the company has diversified and has since worked in

RAIL

AEROSPACE

ARMOURY/DEFENCE

POWER

RENEWABLE ENERGY

RAIL

AEROSPACE

ARMOURY/DEFENCE

POWER

RENEWABLE ENERGY

OUR SERVICES

OUR SERVICES

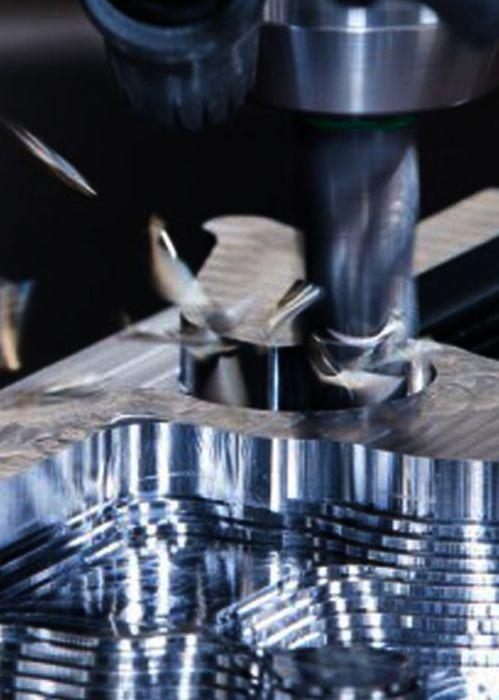

MACHINING

Milling and Turning capabilities are unparalleled & cover from precision small component machining to medium sized engineered components of up to 3m in length and up to 5 tons.

SPECIALISED WELDING

Includes, but is not limited to: Welding Stainless Steel, Welding aluminium, Mild Steel, Carbon Steel, Roqtuff Steel, Robotic, C02 and Tig Welding Machines

DEEP DRILLING

Cor-Tech has Deep Drilling facilities up to 640mm deep, using diameter 8drill to 11 drill. This facility is ideal for drilling long shafts & is another speciality procedure provided by Cor-Tech

WIRE CUTTING

Cor-Tech invested in a Sodick Wire Cutting Machine. This enables us to cut any component with intricate shapes and forms that is otherwise difficult to machine with a CNC machining center. Items include splines and gears. We can hold components with a diameter of 350mm by 150mm high.

IN-HOUSE QUALITY AND INSPECTION SERVICE

We operate an in-house quality assurance program that conforms in all aspects to international standards. All procedures and testing are in strict conformance to quality plans, prepared according to customer requirements.

MAXI CYLINDRICAL GRINDER

Our Maxi cylindrical grinder enables us to grind all critical diameter in-house. Length between centers: 2 meters. Swing over the table of 400mm. We can grind OD’s from 8-320mm. It has an internal attachment that can grind internal diameters from 30-100mm.

REBUILDS/REPAIRS

Cor-Tech offers total rebuild &repairs services for different types of parts and machinery.

SLOTTING AND SPLINING

We are proud to announce that we have invested in a CNC Slotting Machine and going forward all Slotting and Splining will be carried out in-house.

SOLID MODELING

Cor-Tech uses VisiCam software and works in a Solid Modeling enviroment.